Tutorial: Steps In The Design Of A 2-Way Spanning Slab With BS8110

Let’s talk about Slab Design…

How can you design a 2 way spanning slab and be able to know the reinforcement size to be used in your slab as well as the spacing needed when tieing your reinforcements.

So on this post, you’ll be able to have a clue on how to design a 2 way spanning slab. You’ll know the following:

How to determine the Ultimate Load, F

How to calculate the dead load

How to determine the ratio ly/lx

How to check for deflection.

Now let’s begin…..!

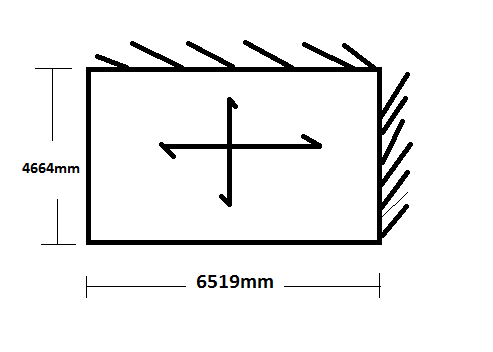

Let’s assume you’re given a part floor plan for a residential building just as I’m going to draw below. Let’s also assume the floor consist of a 150mm thick slab cast insitu with edge beams. Also assume the design data which I’m going to list below have been provided for you as a young practicing engineer.

Now how do you design a 2 way spanning slab?

Check out the design data given below:

Design Data

Characteristic live load, Qk = 1.5KN/m²

Partitioning, Let’s Assume. = 1.1KN/m²

Finishing, Say. = 1.2KN/m²

Concrete Grade (fcu). = 20KN/m²

Characteristic strength of steel (mild), fy. = 250KN/m²

Concrete Cover, c = 20mm

Solution

Let’s determine the loading

Concrete own weight (0.15 x 24) = 3.6KN/m²

Partitioning = 1.1KN/m²

Finishing. = 1.2KN/m²

______________________________________________________

Total Dead Load, Gk. = 5.9KN/m²

______________________________________________________

Ultimate Load, F:

F = 1.4Gk + 1.6Qk

But Gk = 5.9KN/m², Qk = 1.5KN/m²

Therefore: F = (1.4 x 5.9) + (1.6 x 1.5)

Ultimate load, F = 10.66KN/m²

Determine the Ratio ly/lx

Ratio ly/lx is determine by dividing the longest span of the slab by the shorter span.

The shortest as well as longest span can be known by looking at the dimensions of the slab as shown below.

For the slab in question, ly = 6519: lx = 4664

Therefore 6519/4664 = 1.4

>>Effective Depth = thickness – concrete cover – 1/2 bar size

d = 150-20-10/2 = 125mm

>>Determine the Moment

Short Span: (Edge (B) = 0.074, Span = 0.055 ( Obtained from the BS Code)

M = Bwlx² = Bflx²

Mid span: m = 0.055 x 10.66 x 4.664²

M = 12.75KNm

Continuous Edge: M = 0.074 x 10.66 x 4.664²

M = 17.16 KNm

Long Span: (edge (B) = 0.045, span (B) = 0.034)

M = Bflx²

Mid Span: m = 0.034 x 10.66 x 4.664²

= 7.9KNm

Continuous Edge: m = 0.045 x 10.66 x 4.664²

= 10.44KNm

Design Proper….!

Short Span

Mid-Span: K = (m/fcubd²) = (12.75 x 106)/20 x 1000 x 125²

K = 0.041

Lever Arm, la = 0.5 + √0.25 – (k/0.9) = 0.5 + √0.25 -(0.041/0.9)

La = 0.95

As = M/0.95fylad = 12.75 x 10^6/0.95 x 250 x 0.95 x 125

As = 452mm²

Provide Y12 @200mm c/c Btm (566mm²)

Continuous Edge:

K = (M x 16 x 106)/20 x 1000 x 125²

K = 0.055

Lever Arm, la = 0.5 + √0.25 – (k/0.9) = 0.5 + √0.25 -(0.055/0.9).

La = 0.94

As = (17.16 x 10 ^6)/(0.95 x 250 x 0.94 x 125)

As = 614.9 or 615mm²

Provide Y12 @ 150mm c/c btm (754mm²)

Long Span

Mid-span: K = (7.9 x 106)/(20 x 1000 x 125²)

K = 0.024

Lever Arm, la = 0.5 + √0.25 – (k/0.9) = 0.5 + √0.25 -(0.024/0.9)

= 0.97

Since LA value is greater than 0.95, we use 0.95

As = (7.9 x 106)/(0.95 x 250 x 0.95 x 125)

As = 280mm²

Provide Y10 @ 200mm c/c top (393mm²)

Continuous Edge

K = 10.44 x 106/20 x 1000 x 125²

K = 0.033

Lever Arm, la = 0.5 + √0.25 – (k/0.9) = 0.5 + √0.25 -(0.033/0.9)

La = 0.96

But we use, la = 0.95

As = 10.44 x 106/(0.95 x 250 x 0.95 x125)

As = 370mm²

Provide Y12 @225mm c/c top (502mm²)

Check For Deflection

Fs = 2AsReq/3As Provided

Fs = (2 x 250 x 452)/(3 x 566) = 133.1 deflection is OK

So this is how to design a 2 way spanning slab using BS8110

As you can see all the parameters has been carefully analysed and solved for so you can follow this step if you ever encounter a 2 way spanning slab in your design process.

Please Note:

1. This will only be familiar to those that are used to the basics of structural design.

2. The design Data are values selected before you begin to design

3. Parameters will be explained in other articles on this blog so keep a date with us.

where do you get the table for area of steel so as to find the reinforcement required?

BS Code…

If you're a Nigerian, you can find it on Victor Oyenuga's Textbook